The Work Order functionality is used to raise Work Orders for Assemblies. These are products which are made up of a number of items and then assembled on site.

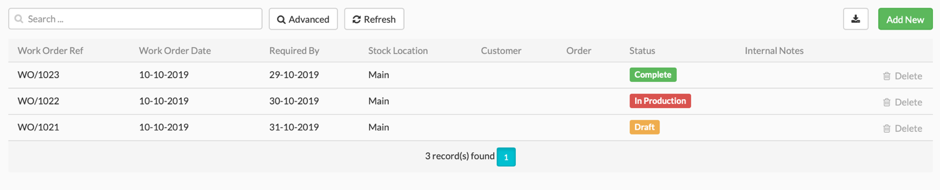

Work order display shows all the work orders that have been created in the system with the status of each work order.

Fig 47 Work Order Display

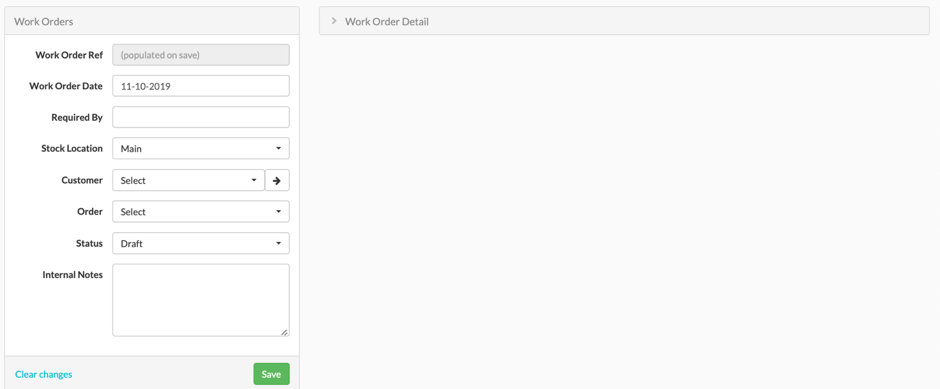

To create a new Work Order select the Add New button.

Fig 48 Work Order – Add

Enter the details of your Work Order and Save. Details of fields are in the table below.

| Work Orders | ||

| Name of Field | Mandatory | Description |

| Work Order Ref | Default | A system generated number which defaults when you save the Work Order. |

| Work Order Date | Y | The Date of this work order. Defaults to today’s date but can be changed. |

| Required By | Y | The date by which the Work is required to be complete. Picked from a Date Picker. |

| Stock Location | Default | Defaults to the Main stock location and it is possible to change this if you’re creating a work order for a different location. |

| Customer | N | If you are creating the Assembly for a particular customer order then you can pick the customer here from a dropdown of all customers. |

| Order | N | If you are creating the Assembly for a particular customer order then you can pick the order number here from a dropdown of all orders for this customer. |

| Status | Default | The status of this work order. This defaults to Draft and the other options are In Production and Complete. |

| Internal Notes | N | Any notes pertaining to this work order. |

Note: A Work Order may be associated with a Customer Order or it may not. It’s possible/probable that you might wish to create assemblies to hold in stock so that they are ready to be despatched quickly.

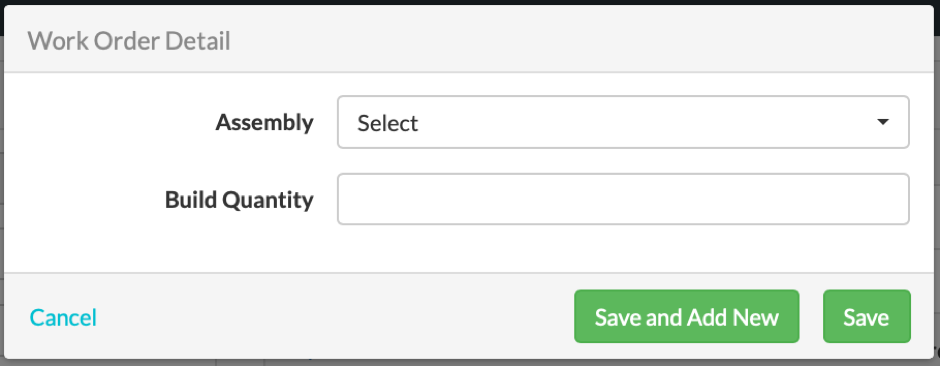

Once you’ve added your Work Order you need to define which Assemblies you want to make. On the right-hand side is the Work Order Detail section. Select + New:

Fig 49 Work Order Detail

Add the name of the Assembly you wish to make and the number. The Assembly field will show a dropdown of all Assemblies that have been entered in the Assembly section of the Product Catalogue. Then add the number of assemblies you wish to make.

As the work on the Assembly progresses you can change the status of the Work Order to “In Production” and then “Complete”, at which point the Assembly will show as “In Stock” and the constituent parts will be taken out of stock.